Expected project duration: 1 week (i.e. 2 lab sessions)

Project type: individual

In today’s labs, we investigate the RC circuit, which is a capacitor in series with a resistor. We will use the signal generator to apply different voltage signals to the RC circuit and the oscilloscope to see how it responds.

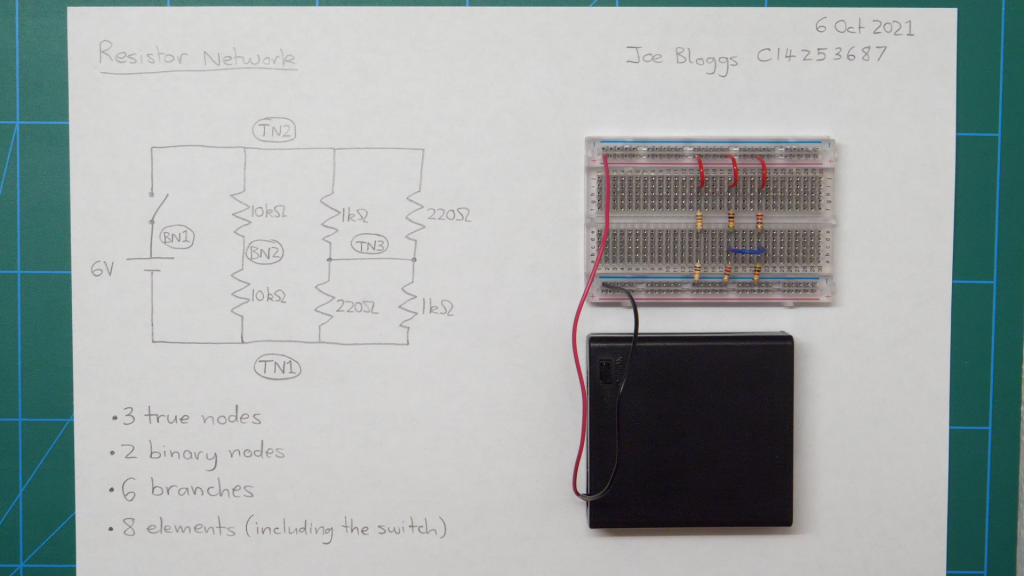

A detailed report is not required for this short project, but you will submit a Word document containing five items of evidence to Brightspace. State the following at the beginning of the Word document:

- Your name

- The date

- Module code (ELEC 1011)

- Project title (“RC circuit step response and frequency response”)

The five items of evidence to include in the Word document are:

- Breadboard photograph,

- Photo of step response displayed on oscilloscope,

- Photo of time constant calculation on paper,

- Photo of sinusoidal AC waveforms on oscilloscope,

- Excel plot of magnitude response of the RC circuit.

More details about each item of evidence are provided below. No additional text or other content is required in the Word document.

Background theory

You’re already familiar with resistance and with Ohm’s law, which describes the relationship between the voltage across a resistor and the current flowing through it.

where is the instantaneous voltage (in volts) between the terminals of the resistor,

is the instantaneous current (in amperes) flowing through it, and

is the resistance (in ohms). This means that at every moment in time, the current flowing through a resistor is proportional to the voltage across it at that instant. This remains true even when the voltage applied to the resistor is varying over time, as is the case with an AC voltage. When you apply a sinusoidal voltage to a resistor, you get a sinusoidal current with a magnitude that depends on the resistance. The voltage and current waveforms are exactly in phase, which means that they’re perfectly aligned in time – the peak current occurs at the same time as the peak voltage.

The relationship between voltage and current in a capacitor is more complicated.

where is the instantaneous voltage (in volts) between the terminals of the capacitor,

is the instantaneous current (in amperes) flowing through it, and

is the capacitance (in farads). What this means is that the current is proportional to the rate of change of voltage. So when an AC voltage is applied to a capacitor, the magnitude of the current depends on how fast the voltage is changing.

- If the frequency of the AC voltage is high (meaning that the voltage is constantly changing very rapidly), then the current will be large because the capacitor doesn’t impede it very much.

- Conversely, if the frequency of the AC voltage is low (meaning that the voltage is only changing relatively slowly), then the capacitor impedes the current a lot.

This leads us to the concept of impedance which tells us how much an element (resistor, inductor or capacitor) impedes the flow of electric current. We can also calculate the impedance of a circuit made up of any combination of resistors, inductors and capacitors.

Conventionally, impedance values are represented using an upper case letter Z. In general, impedance is a complex number. However, the impedance of a resistor is purely real (i.e. it has zero imaginary part). The impedance of a resistor is simply equal to its resistance:

where is the resistance (in ohms) and

is the impedance of the resistor (in ohms).

The impedance of a capacitor is purely imaginary (i.e. its real part is zero). It depends on two things: the capacitance and the frequency of the current.

where is the imedance of the capacitor (in ohms),

is the capacitance (in farads),

is the imaginary unit (i.e.

), and

is the angular frequency (in rad/s).

Angular frequency represents the same property of a signal as frequency, but in different units. Whereas frequency is measured in hertz (cycles per second), angular frequency is measured in rad/s (radians per second). When working with impedances, using angular frequencies greatly simplifies the arithmetic.

Frequency, , in hertz and angular frequency,

, in rad/s are related as follows.

Last semester, we learned various approaches for analyzing circuits made up of resistors and DC voltage and current sources. In the coming weeks, we will learn how to apply the same techniques to circuits made up of resistors, inductors, capacitors, and sinusoidal voltage and current sources. The key to doing this will be representing the sinusoidal voltages and currents using complex values known as phasors, and by converting all of the resistors, capacitors and inductors into impedances.

If you think of impedance as an extension of the concept of resistance, then a capacitor is “like a resistor” that changes its resistance depending on the frequency of the current flowing through it. High frequencies pass through easily. Low frequencies find it much harder to pass through.

Because impedance is a complex number (having a magnitude and an angle) it also introduces a phase shift between voltage and current waveforms. In a capacitor, the current waveform leads the voltage waveform by exactly (equivalent to

radians) – i.e. one quarter cycle.

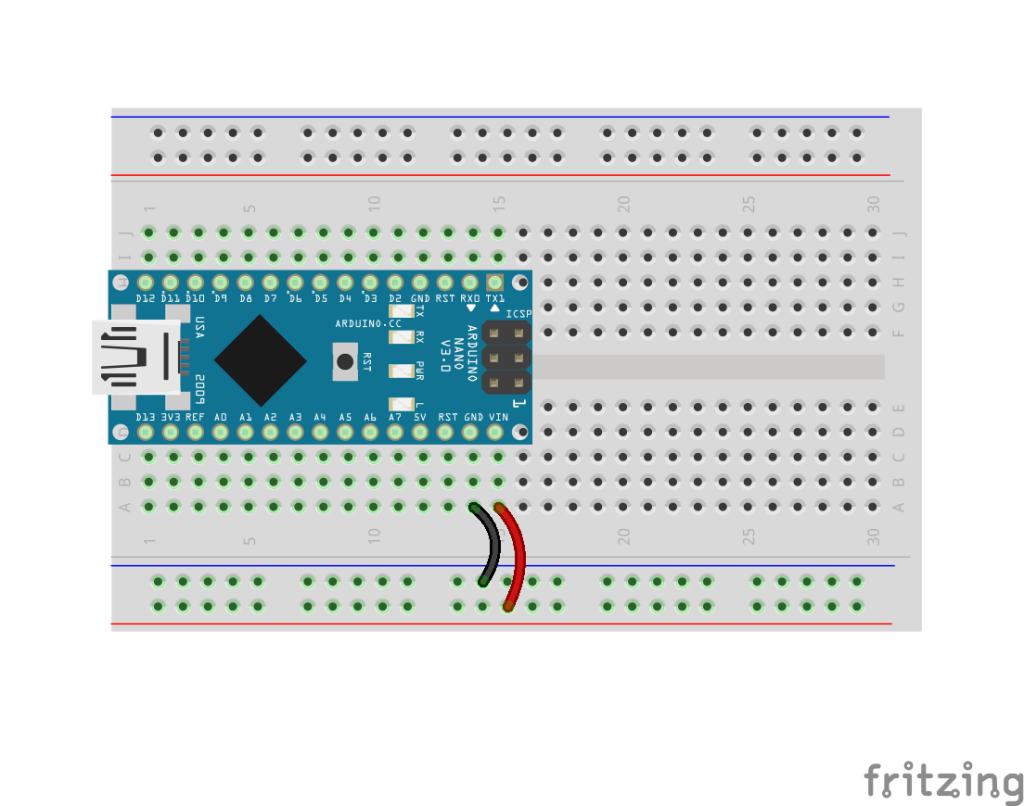

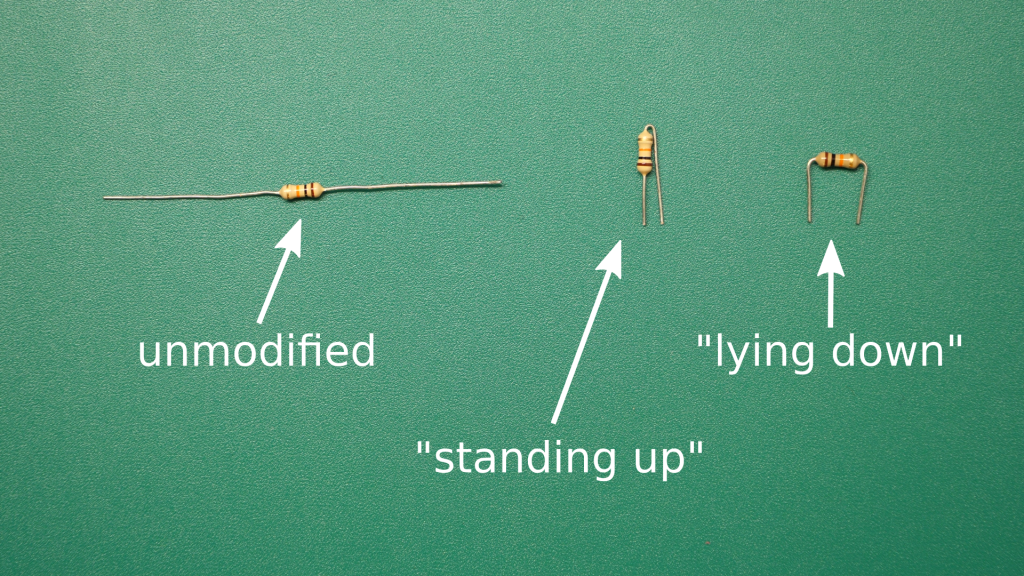

Part 1: Construct the RC circuit on the breadboard

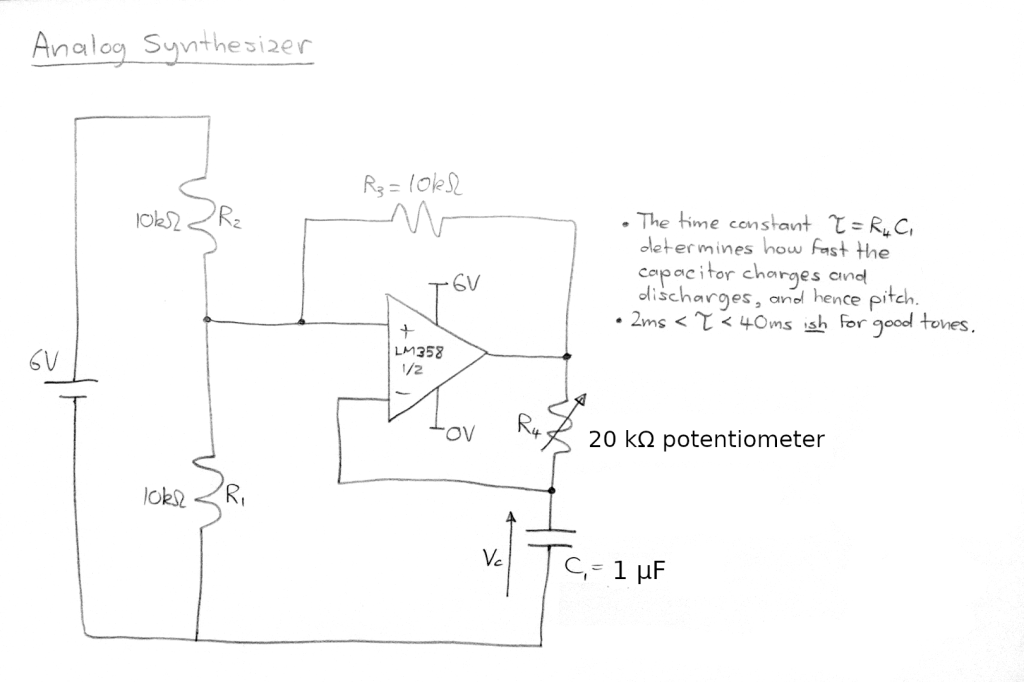

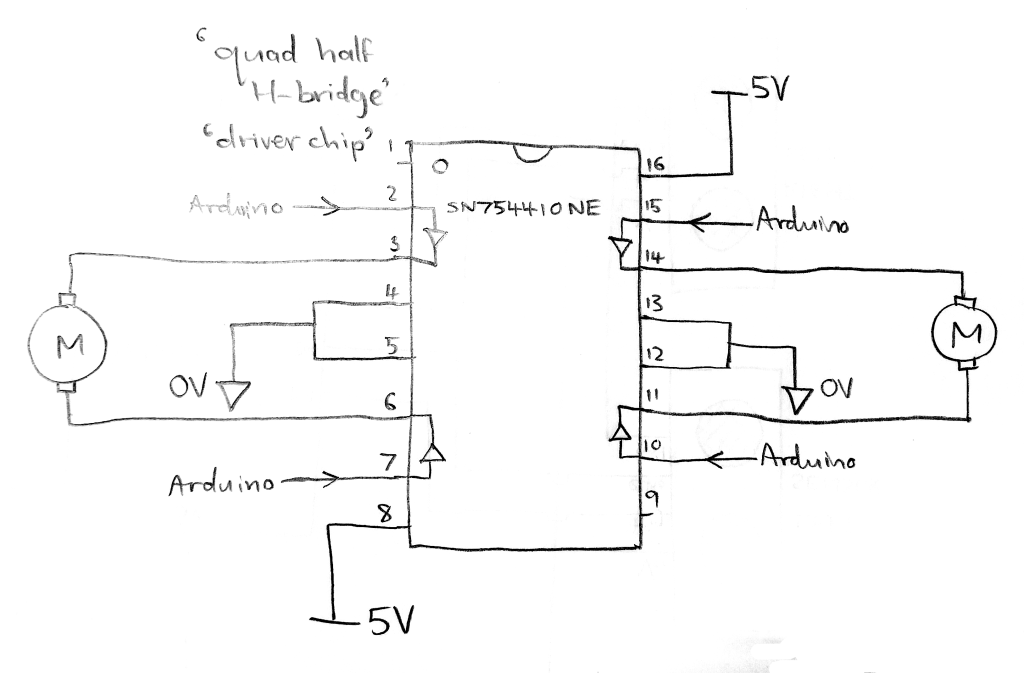

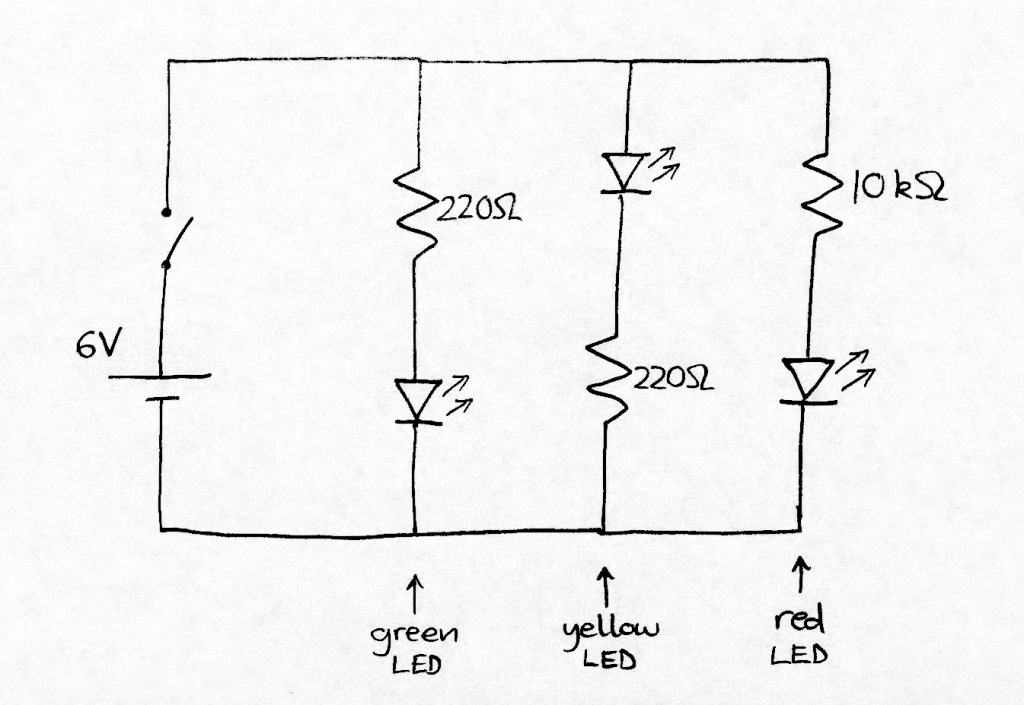

The circuit shown below is the basis for today’s experiment.

- Your instructor will provide you with the 1 kΩ resistor and 220 nF capacitor.

- For the voltage source on the left, use the signal generator available in the laboratory.

- The volt meter symbols on the right represent the two channels of the oscilloscope. Channel 1 is used to measure the input voltage signal applied to the complete RC circuit. Channel 2 is used to measure the voltage across the capacitor on its own.

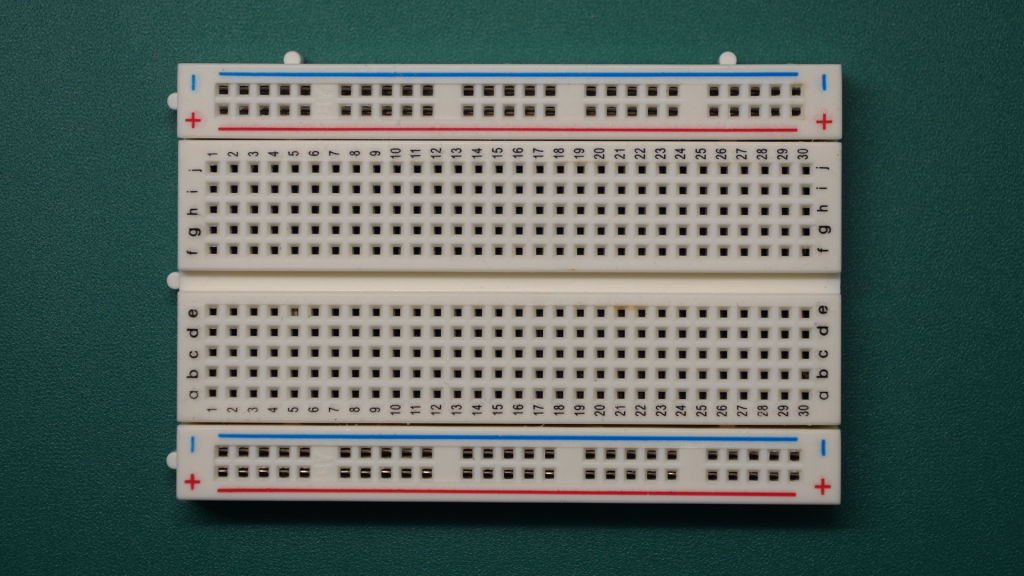

The photo below shows the RC circuit built on a breadboard, with the resistor and capacitor placed in series. The red and black wires at the left side of the photo are supplying the input voltage signal from the signal generator. During this experiment, you will apply several different input voltage signals to see how the circuit responds.

The oscilloscope connections are not shown above, but the two probes should be connected as follows:

- Connect the ground connection of each oscilloscope probe to the negative rail at the lower side of breadboard.

- The signal connection for scope channel 1 can be connected to the red rail at the upper side of the breadboard to measure the input voltage coming straight from the signal generator.

- The signal connection for scope channel 2 can be connected to the circuit node between the capacitor and the resistor (e.g. point h15 on the breadboard in the above photo).

EVIDENCE ITEM 1: Take a clear photograph of your complete breadboard circuit, including the connections to the signal generator and oscilloscope.

Part 2: Step response of the RC circuit

In this part of the experiment, you will apply an input voltage signal to the RC circuit that goes through a step change (increasing abruptly from 0 V to 5 V) and observe how the capacitor voltage changes in response.

The expected step response of the RC circuit is shown above. The black waveform, , is the input voltage signal. The red waveform,

, is the capacitor voltage, which exhibits the exponential step response.

The input voltage (black line) increase abruptly, but the capacitor voltage

(red line) rises more slowly and approaches the input voltage asymptotically. This red curve is the step response of the RC circuit.

Useful information about a system can be gleaned from its step response. For example, we can measure the time constant of this system from the step response.

To measure the step response of your RC circuit:

- Set the signal generator to output a square wave with 5 V amplitude and very low frequency (e.g. 10 Hz).

- Display both traces (channels 1 and 2) on the screen of the oscilloscope.

- Set the oscilloscope trigger source as channel 1 (the step input).

- Set the trigger level to a value in between 0 V and 5 V.

- Adjust the time and voltage scaling to display a clear view of the step response.

- Estimate the time constant (in seconds) by measuring it from the oscilloscope screen. Refer to the diagram above to see what you need to measure.

- On a piece of paper, calculate the expected time constant of the RC circuit, using the formula provided in the diagram above. Write down the time constant measured from the oscilloscope. Do the measured and expected values agree?

Ask your lab instructor if you need help with the controls on the signal generator or oscilloscope.

EVIDENCE ITEM 2: Take a clear photograph of the step response of the RC circuit displayed on the oscilloscope screen.

EVIDENCE ITEM 3: Take a clear photograph of the page showing your time constant calculation.

Part 3: Frequency response of the RC circuit

In this part of the experiment, you will apply voltage signals of different frequencies to the RC circuit and observe how the magnitude and phase of the capacitor voltage vary (relative to the input voltage). You will plot a graph of the magnitude response of the RC circuit.

To begin,

- Configure the signal generator to output a sinusoidal waveform with an amplitude of 1 V and a frequency of 1 kHz. Verify that the signal appears correctly on the oscilloscope.

- Select the same time and voltage scaling on both channels of the oscilloscope so that you can compare the waveforms directly.

- Verify that the capacitor voltage is also sinusoidal. You should see that it has smaller amplitude than the input signal and that there is a phase shift between the two signals.

EVIDENCE ITEM 4: Take a clear photograph of the input voltage (1 V amplitude and 1 kHz frequency) and capacitor voltage waveforms displayed on the oscilloscope.

To plot the magnitude response of the RC circuit, use the oscilloscope to measure the amplitude of the capacitor voltage waveform over a range of frequencies. You may need to adjust the signal generator controls to ensure that the input voltage amplitude remains constant at every frequency. However, the capacitor voltage amplitude is expected to change because the impedance of the capacitor reduces as frequency increases. You will also observe that the phase shift between the voltage waveforms changes with frequency.

Measure the capacitor voltage amplitude at the following frequencies: 10 Hz, 30 Hz, 100 Hz, 300 Hz, 1 kHz, 3 kHz, 10 kHz, 30 kHz, 100 kHz, 300 kHz. Use Excel to tabulate your results and plot a graph of the magnitude response.

- Label the horizontal axis as “Frequency [Hz]”. You may need to select a log scale on that axis.

- Label the vertical axis as “Amplitude [V]”.

- Add a suitable title to the graph (e.g. “Magnitude response of RC circuit”).

EVIDENCE ITEM 5: Copy and paste your Excel graph into your Word Document.

Finally, submit your complete Word document containing the five items of evidence to Brightspace.